Allfast offers a lineup of temporary tack fasteners to facilitate automated fastening, reduce cycle time and improve assembly efficiency with excellent hole fill, clamp up and drill out properties. Allfast can supply the right tack fastener tailored to your application.

FASTACK, SUPERTACK, FASTACK SC

Key Features:

- Good hole fill

- Extended grip and hole range

- Excellent Clamp-Up ability

- Extensive cycle time reduction

- Temporary rivet to facilitate automated fastening

The family of Temporary Rivets produced by Allfast present the right rivet for your automated fastening application. Used worldwide, these temporary rivets have improved cycle times significantly. These fasteners are designed to hold components together for automated fastening of aerospace assemblies.

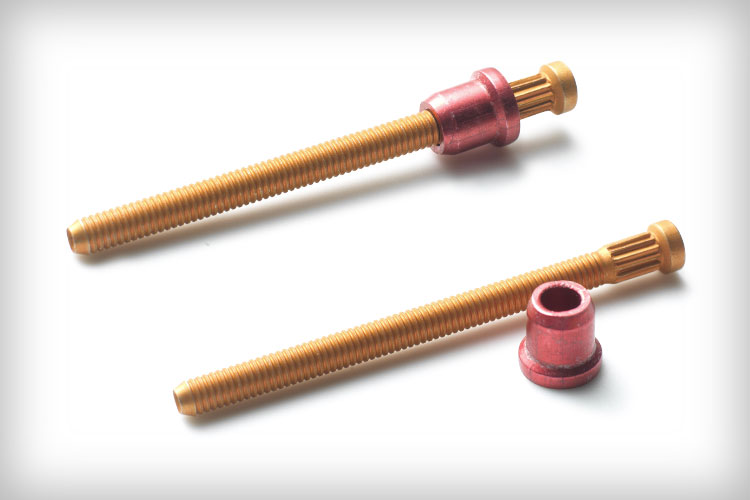

The FASTACK and SUPERTACK temporary rivets, consisting of a pin and sleeve, are a pull through design.

The pin is drawn through the sleeve, expanding the sleeve to join components in a simple dependable manner. This fastener temporarily tacks components together to facilitate automated fastening using permanent fasteners. The FASTACK offers extended hole and grip range capabilities. For improved clamp up, shear, and tension strength, the SUPERTACK is the right fastener.

The FASTACK SC temporary rivet, consisting of a pin and sleeve, is a shear ring bulbing type design.

The pin is drawn into the sleeve, expanding the sleeve forming a bulb on the blind side. This action creates Superior Clamping (SC). The shear ring fractures and allows the pin to pull through the sleeve. The resulting tack location offers increased clamping, shear and tension properties.

FASTACK and SUPERTACK Part Numbers & Technical Drawings:

| Part Family | Prefix | Sleeve Material | Pin Material | Head Style | Shank Type | Technical Drawing |

|---|---|---|---|---|---|---|

| FASTACK | AF5055 | 5056 Aluminum | Mild Steel | Tack Head | Nominal | |

| FASTACK | AF5056 | 5056 Aluminum | Mild Steel | Tack Head | Nominal | |

| SuperTack | AF5022 | 2017 Aluminum | Cres | Reduced Tack Head | Nominal | |

| SuperTack | AF5075 | 2017 Aluminum | Cres | Tack Head | Nominal | |

| SuperTack | AF5076 | 2017 Aluminum | Cres | Oversize Tack Head | Nominal | |

| FASTACK SC | AF5065 | 5056 Aluminum | Cres | Tack Head | Nominal |

TACKBOLT

Key Features:

- Designed for Heavy duty tacking applications

- Generous sheet take-up capacity

- Extended grip range

- Temporary fastener to facilitate automated fastening

The TACKBOLT temporary fastener, consisting of a pin and collar, is designed to facilitate automated fastening and reduce cycle time.

The pin is inserted into the components to be joined. From the opposite side, the collar is applied to the pin. The installation tool is used to pull on the pin applying clamping pressure to the joint. The nosepiece of the tool swages the collar onto the pin, creating a mechanical lock. The pull portion of the pin is separated from the installed fastener.

The TACKBOLT offers extended grip range capacity. One part number accommodates over 1 inch of grip range. The TACKBOLT offers exceptional sheet take-up, shear and tension properties.

With all the Allfast temporary fasteners, the TACKBOLT is easily removed by drilling to prepare a hole for permanent fastener installation. This concept streamlines permanent faster automation. Cycle time reduction and labor savings can be realized.

TACKBOLT Part Numbers & Technical Drawings:

| Part Family | Prefix | Sleeve Material | Pin Material | Head Style | Shank Type | Technical Drawing |

|---|---|---|---|---|---|---|

| TACKBOLT | AF3675 | 5056 Aluminum | 7075 Aluminum | Tack Head | Nominal | |

| TACKBOLT | AF3675 | 5056 Aluminum | 7075 Aluminum | Tack Head | Nominal | |

| TACKBOLT | AF3675 | 5056 Aluminum | 7075 Aluminum | Tack Head | Nominal | |

| TACKBOLT | AF3676 | 5056 Aluminum | 7075 Aluminum | Tack Head w/ Chip Break | Nominal |