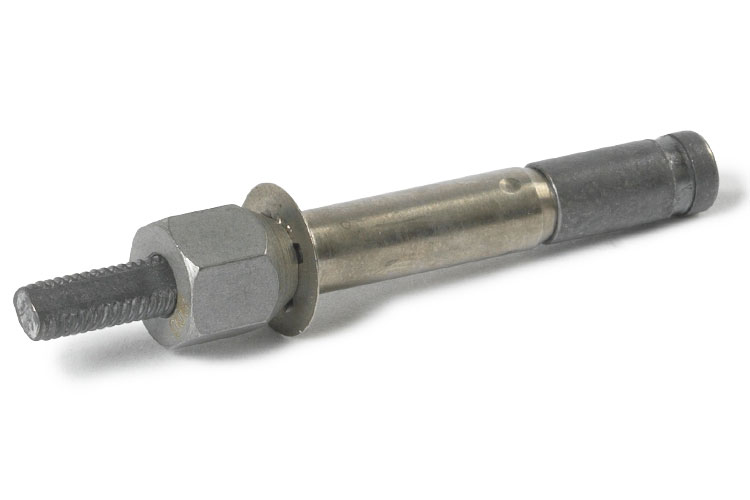

Designed for use in composite laminates but equally well-suited to metal structure, the Composi-Lok® family of fasteners provides superior joint integrity. Today, Composi-Lok® is approved on virtually all composite airframe programs throughout the world. The new Composi-Lok3, in keeping with Monogram’s commitment to a lower installed cost design philosophy, is shave-free, providing the performance and reliability of our Composi-Lok® with the added benefits of a flush break.

Key Features

All Composi-Loks® provide these important advantages:

- Large blind upset eliminates composite damage

- Easy, labor-saving one-sided installation further simplified by the drive nut concept

- Controlled clamp-up – no gaps and tighter assemblies

- Completely compatible with graphite – available in titanium or CRES materials to resist galvanic corrosion

- Visual locking feature resists loosening due to vibration

- Fuel-tight sealing capability

Find a Distributor

Use the link to find an authorized Monogram Aerospace Fasteners distributor near you.

Providing Superior Joint Integrity

By providing a large blind-side upset, hailed by some as the industry benchmark, Composi-Loks® distribute bearing loads over a large area, overcoming damage to the composite. The characteristic large blind-side bearing area or “footprint” allows the fastener to impart very high clamp loads to the structure without damage to the composite. Structural integrity in severe vibration environments is assured by a patented locking feature. Proper installation can be achieved with simple and compact hand or power tools and verified from one side of the structure by measurement of the screw break-off position. Available in four distinct 75 KSI shear strength versions, all Composi-Loks® are completely compatible with graphite and are not subject to galvanic corrosion. Composi-Loks® are available in 5/32″ through 3/8″ diameters, including oversizes, and have a .050″ operational grip range.

Composi-Lok II

For automated or robotic assembly, Composi-Loks® can also be supplied with Monogram’s Double Cylindrical Drive (DCD) system. The DCD system provides a common tool interface regardless of head style, fastener grip, or diameter. And, because the interface and drive mechanism are cylindrical, there are no orientation problems!

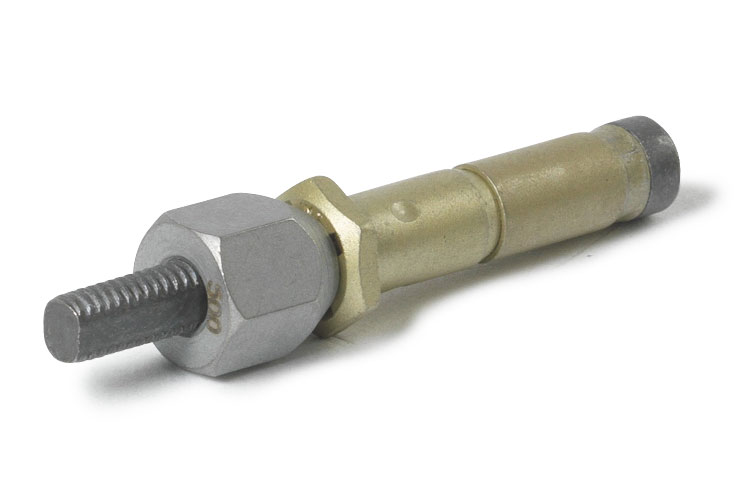

Composi-Lok IIa

Composi-Lok IIa fasteners, with their unique design characteristics, address the inherent thickness variations of composite material stack-ups. These common variations make proper grip measurement practices imperative to assure proper fastener performance and joint integrity. These concerns are minimized by the ability of the Composi-Lok IIa to function properly even when installed .050″ beyond its prescribed grip accommodation.

While design considerations should be limited to the optimum performance characteristics of the fastener within its prescribed .050″ grip range, the added assurance of joint integrity in limited out-of-grip conditions is available with Composi-Lok IIa. This extended grip capacity of .025″ under minimum grip to .025″ over maximum grip (for a total of .100″) with no composite damage and joint performance still in excess of guaranteed minimums makes the Composi-Lok IIa one of the most tolerant blind fasteners for composites on the market.

Composi-Lok3

Composi-Lok3 is the newest cost-saving design in the Composi-Lok series. With one of the most trusted names in aircraft assembly as its foundation, Composi-Lok3 delivers lower installed costs and increased productivity. Designed to afford a flush to below-flush break-off, the Composi-Lok3 requires no secondary shaving, milling, or grinding operations to meet aerodynamic flushness requirements. All the performance and reliability of our Composi-Lok is now available with a flush break-off. Without compromise on mechanical properties, high preloads, or large blind side head formation, you save on tooling expense as well as the time and cost of shaving while productivity is increased with labor dedicated to other tasks.

Part Numbers & Technical Drawings

| Part Family | Prefix | Material | Head Style | Shank Type | Special Features | Rated Shear Strength | Technical Drawing Downloads |

|---|---|---|---|---|---|---|---|

| Composi-Lok | MBF2010 | Titanium | Protruding | Nominal | Low Profile Head | 75 KSI | |

| Composi-Lok | MBF2011 | Titanium | Hex | Nominal | Reduced Head | 75 KSI | |

| Composi-Lok | MBF2012 | Titanium | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2013 | Titanium | 130 Degree Shear | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2110 | Titanium | Protruding | Nominal | Low Profile Head | 75 KSI | |

| Composi-Lok | MBF2111 | Titanium | Hex | Nominal | Reduced Head | 75 KSI | |

| Composi-Lok | MBF2112 | Titanium | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2113 | Titanium | 130 Degree Shear | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2120 | A286 Cres | Protruding | Nominal | Low Profile Hd | 75 KSI | |

| Composi-Lok | MBF2121 | A286 Cres | Hex | Nominal | Reduced Hd | 75 KSI | |

| Composi-Lok | MBF2122 | A286 Cres | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2123 | A286 Cres | 130 Degree Shear | Nominal | - | 75 KSI | |

| Composi-Lok | MBF2130 | A286 Cres | Protruding | Nominal | Interference Fit | 90 KSI | |

| Composi-Lok | MBF2132 | A286 Cres | 100 Degree Tension | Nominal | Interference Fit | 90 KSI | |

| Composi-Lok | MBF2133 | A286 Cres | 130 Degree Shear | Nominal | Interference Fit | 90 KSI | |

| Composi-Lok | MBF2134 | A286 Cres | 100 Degree Reduced Shear | Nominal | Interference Fit | 90 KSI | |

| Composi-Lok | MBF2140 | Titanium | Protruding | Nominal | Low Profile Hd / Ti Screw For Wt. Savings | 75 KSI | |

| Composi-Lok | MBF2141 | Titanium | Hex | Nominal | Reduced Hd / Ti Screw For Wt. Savings | 75 KSI | |

| Composi-Lok | MBF2142 | Titanium | 100 Degree Tension | Nominal | Ti Screw For Wt. Savings | 75 KSI | |

| Composi-Lok | MBF2143 | Titanium | 130 Degree Shear | Nominal | Ti Screw For Wt. Savings | 75 KSI | |

| Composi-Lok | MBF2310 | Titanium | Protruding, Low Profile | Nominal | Flush Break / No Shaving | 75 KSI | |

| Composi-Lok | MBF2312 | Titanium | 100 Degree Tension | Nominal | Flush Break / No Shaving | 75 KSI | |

| Composi-Lok | MBF2313 | Titanium | 130 Degree Shear | Nominal | Flush Break / No Shaving | 75 KSI | |

| Composi-Lok | MBF2315 | Titanium | 130 Degree Shear | Nominal | Reduced Recess / Flush Break / No Shaving | 75 KSI | |

| Composi-Lok | MBF2322 | A286 Cres | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF3003 | Titanium | Protruding | Nominal | Low Profile Hd | 75 KSI | |

| Composi-Lok | MBF3004 | Titanium | Hex | Nominal | Reduced Hd | 75 KSI | |

| Composi-Lok | MBF3005 | Titanium | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF3006 | Titanium | 130 Degree Shear | Nominal | - | 75 KSI | |

| Composi-Lok | MBF3008 | A286 Cres | Protruding | Nominal | Low Profile Hd | 75 KSI | |

| Composi-Lok | MBF3010 | A286 Cres | 100 Degree Tension | Nominal | - | 75 KSI | |

| Composi-Lok | MBF3011 | A286 Cres | 130 Degree Shear | Nominal | - | 75 KSI | |

| Composi-Lok | MBF3012 | Titanium | Protruding | 1/64 Oversize | Low Profile Hd | 75 KSI | |

| Composi-Lok | MBF3013 | Titanium | 130 Degree Shear | Nominal | Crown Head | 75 KSI | |

| Composi-Lok | MBF3015 | A286 Cres | Protruding | 1/64 Oversize | Low Profile Hd | 75 KSI |